Dr. Jay McCormack; Rose-Hulman – Associate Professor Mechanical Engineering

I teach classes in both the mechanical engineering and engineering design programs at Rose-Hulman Institute of Technology in the areas of design and manufacturing. Rose is a small college in Terre Haute, Indiana focused on STEM. In the mechanical engineering program, one of the courses that we find differentiates our graduates is a junior level course on design for manufacturing. Instead of focusing on the sciences of manufacturing processes (which is clearly very valuable also), our course focuses on the application of design principles to facilitate the manufacturing of a given product, comparison of various manufacturing methods, and supporting design best practices related to manufacturing such as geometric dimensioning and tolerancing.

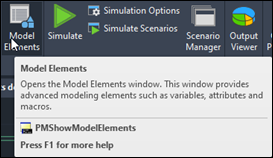

Two years ago, one member of the teaching team, the original creator of our design for manufacturing class, proposed integrating a process simulation project into the course. Our students are exposed to many manufacturing methods and work in depth with a few, but never had any exposure to manufacturing process. This is arguably appropriate content for any mechanical engineer but, a robotics minor is popular with our mechanical engineers, and many of the robotics students end up in positions related to manufacturing. Additionally, many biomedical engineers take the course and end up working as process engineers for medical device manufacturers. Therefore, the need was there for students to get a first exposure to manufacturing process and process simulation. I had some experience with process simulation more than a decade ago and experience with lean manufacturing so I was elected (appointed) by the teaching team to develop the project. I was familiar with ProModel products, but it had been a while since I used any simulation tools. I evaluated Process Simulator, a tool from ProModel that installs as a plug in to Microsoft Visio, and several other products, but found that Process Simulator allowed me to get students from zero to their first model quickly. After choosing Process Simulator and discussing the options to get the software from ProModel, I started developing the project.

Project Outcomes

My first objective was to develop the learning outcomes for the project. There were a few factors driving the learning outcomes:

- The students were almost exclusively novices. Virtually none of the 175 students in the course had any experience with any process simulation software, so the learning outcomes had to include low Bloom’s level items focused on both manufacturing topics and Process Simulator concepts.

- The design for manufacturing course itself has a number of bottlenecks involving other projects. Several hands on course projects involve specialized equipment and technician time. These projects require creative scheduling to get all students equal access to these resources in an eight-week period. Consequently, the learning outcomes and process simulation project were scoped to allow students to work in a self-directed manner with a given set of tutorial videos, feedback from their instructor, and a due dates that varied for project teams.

At the successful completion of this project, students will be able to:

- Define manufacturing process terms – batch, process, inventory, WIP, workstation, buffer, cycle time.

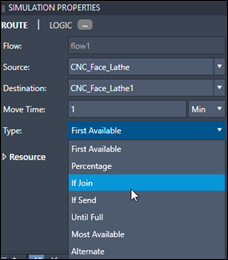

- Define fundamental Process Simulator concepts – entity, resource, activity, routing, arrival, setting simulation properties, batching, buffers, and priority.

- Apply Process Simulator to model a manufacturing process using the fundamental concepts.

- Redesign a manufacturing process using Process Simulator.

Even with just those basic concepts the students were able to create useful Process Simulator models of a given manufacturing process. Additionally, the model was sufficiently complex to require creative experimentation and exploration in order to make improvements.

Project Overview

The objective given to students was to use Process Simulator to model the performance of a factory, suggest improvements to the factory, and measure the impact of the improvements. Excerpts from the project description follow and a link to the complete project description is located at the end of this article.

Scenario

You are an engineer at HOBO Inc. (Hands On Bottle Opener, Inc.), producers of a line of extruded, one-handed bottle openers (The Blue Collar, Figure 1) that appeal to customers through durability, reliability, and functionality. You were on the new product development team that designed a new, beautiful, and refined one-handed bottle opener (The Executive, Figure 2) that will allow you to enter an untapped market. The new design is fabricated using an investment casting process that fits well with the geometric complexity and modest volume of production planned for the new model. Because investment casting is not part of HOBO’s core competency, you will outsource the casting. HOBO will receive a shipment of boxes of unfinished casting trees from the fabricator every morning. Each bottle opener will be sawn from the casting tree then tumbled to remove burrs and to produce better surface finish. Sawing, tumbling, and the subsequent inspection step are among our core competencies, so we plan to perform these operations in house on an existing production line. Additionally, we have two workers that are available on the day shift to be used as much as they are needed. (Note that they will not be fired if they are not used all day. We have work for them elsewhere in the factory.)

This seems like a great opportunity to try the new process simulation software that you are evaluating for purchase. You gathered some baseline data about the operation (see the Factory Description) based on the verbal description by other engineers and managers. The information that you gathered is in the section called Baseline Factory Description.

Baseline Factory Description

There are four workstations. In order, they are:

- Receiving

- Sawing

- Tumbling

- Inspection

There are buffers to store work in process (WIP) located before sawing and before tumbling. A flowchart representing the process is shown in Figure 3. A process box for each workstation and the buffers is shown in Table 1. A more complete description of each is found after the table.

Figure 3. Flow of Materials through the Baseline Factory

Deliverables

| In order to earn a C |

Use Process Simulator software to provide a baseline estimate of net income (revenue – expenses) for the first year of operation. The Baseline Factory must follow all the process rules and procedures outlined in the Baseline Factory Description section. Write a memo summarizing the findings. |

| In order to earn a B |

Design meaningful improvements to the Baseline Factory. Describe the Improved Factory in the memo by capturing each of the suggested improvements. |

| In order to earn an A |

Use Process Simulator to model the Improved Factory. Report the improvement in yearly net income in the memo. |

Details about the baseline factory are provided in subsequent sections, as is a set of tutorial videos that guide students through basic concepts. The videos are a mix of guided examples recorded by me and videos provided by ProModel.

Takeaways

This project was first developed and used in academic year 2018-2019. We were pleased with the enthusiasm that students approached the project and engaged in competition to produce the most profitable manufacturing process compared to their peers. We revised the project for 2019-2020 to include a grading scale that further encouraged exploration and a set of tutorial videos walking students through a given omelet station Process Simulator model.

All of the students received a base level exposure to process simulation, but we were pleased to see that a number of students dove deeper into manufacturing process issues. Students challenged the notion that inspection was required to wait until the last process step, unknowingly suggesting the use of quality at the source, a fundamental lean concept. Those students were able to see the positive impact of quality at the source in their Process Simulator models. Other students had insights about the impact of batch work and how batches served as mechanisms for covering root cause process issues. Those students reduced batch sizes where possible and identified the root cause problems.

The complete project description, scoring rubric, and tutorial video list is linked here. You are welcome to reuse it, modify it, make it better, and/or fix mistakes. If you do, let me know at mccormac@rose-hulman.edu. We look forward to featuring Process Simulator as part of our design for manufacturing course in future years and finding new ways to challenge students to explore manufacturing processes and process simulation.

Bio

Dr. Jay McCormack is an Associate Professor of mechanical engineering at Rose-Hulman Institute of Technology. Dr. McCormack’s teaching and professional development interests are in the areas of design and manufacturing. He teaches courses for the mechanical engineering and engineering design programs as well as the institute’s multidisciplinary design course. Before joining Rose-Hulman, Dr. McCormack was a faculty member at the University of Idaho where he worked with the state’s manufacturing extension partnership. He co-founded Pittsburgh-based CAD tool developer DesignAdvance Systems Inc. after graduating from Carnegie Mellon with a PhD in mechanical engineering.